The Gas Turbine

The emerging prime mover

Authored by: Martin Leduc, March 2001

Brought to you by www.dieselduck.net, comments to [email protected]

The gas turbine is most familiar to people in it�s application to the

aerospace industry. They are found extensively on a wide range of planes and

other aircrafts. Low weight to power ratio, it�s compactness and a

reliable simple design are some of the major advantages of these types of

engine.

The gas turbine is most familiar to people in it�s application to the

aerospace industry. They are found extensively on a wide range of planes and

other aircrafts. Low weight to power ratio, it�s compactness and a

reliable simple design are some of the major advantages of these types of

engine.

They are a precise machine, demanding precision machining and close tolerances. On this web page, we will only cover the basic principles of operation in order to build a knowledge base of marine propulsion plant and their benefits. I believe they will provide a viable alternative to the more common internal combustion prime mover and I encourage you to educate yourself more about them.

For the shipping industry, the advantages of the gas turbine have always been eclipsed by the disadvantages. Principally the high fuel and initial cost have made it an unattractive option for ship owners. The largest consumers of the marine gas turbine has traditionally been the navies and military of the world. Recent developments in gas turbines technology, coupled with lower oil prices (of the late eighties and nineties) and profitability in certain markets as made ship owners reconsider the values of the marine gas turbine. Before we get to these developments and applications, let�s learn more about what is a gas turbine.

How it works...

A turbine is a wheel that absorbs kinetic energy from a fluid stream. Water, steam, air are some fluids. Turbines can come in the form of a windmill, the water turbine of an hydroelectric dam, or the more sophisticated steam turbines or turbo fan under a plane�s wing.

Let�s start simple. With gas turbine, simple involves a kids balloon and a pinwheel. Blow the balloon up, then, while holding the balloon up to the pinwheel, let the air out. As you see the pinwheel turning from the compressed air of the balloon, you can observe the basic principle of a gas turbine, gas compression and the harness of that compression to perform work.

The parts of a gas turbine...

Gas turbine engines are, theoretically, extremely simple. Gas turbine have 3 parts:

Additionally the gas turbine will have these parts:

View a video description of how a gas turbine works, from YouTube.

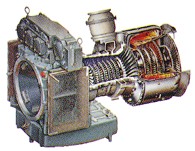

The compressor raises the pressure of the air taken from the atmosphere by a factor from 5 to 20. It is either a centrifugal or axial flow rotating device. It derives it�s driving power directly from the turbine usually mounted on the same shaft.

In the combustion area, the hot compressed air ignites the injected fuel. The fuel is typically a clean, low viscosity petroleum oil. The air / fuel ratio, most likely being 60:1 (by weight), ignites to produce high pressure gas, slightly contaminated with products of combustion. The gas temperature varies from 850 to 1100 degrees Celsius. It is then expanded through a nozzle to convert part of it�s thermal and pressure energy into kinetic energy. The resulting high velocity air stream impinges on the blades of the turbine.

Like all things explained they rarely relay the physical appearance and complexity it seems to have. The gas turbine relies on oil for lubrication of parts. Because of the high temperature reach by the oil leaving the bearing surfaces, 300 degrees as opposed to the normal 100 degrees, the preferred medium is synthetic oils. The passages and conduit for the oil adds to the complex looks, as does the fuel delivery system which must introduce fuel in a uniform fashion throughout the combustor. The fuel is also heat treated to obtain the maximum efficiency from it.

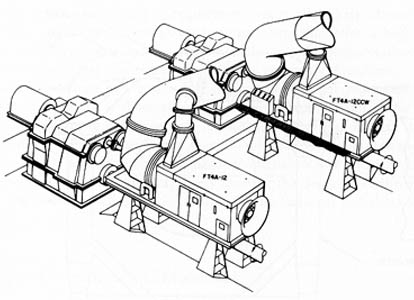

Another "complication" often found on marine gas turbine is the use of two turbine in series. In the above description, the power for the compressor is taken from the turbine itself. In a series setup, the first gas turbine -also know as the compressor drive, high pressure or gas generator provides the drive for the compressor. The second turbine - also know as the low pressure, free or power turbine is better suited to drive the propeller or generator. This splitting of functions, compressor and external load, provides a better torque characteristic such as the one needed for a ship�s propeller. See below for a picture.

The operating environment of the marine gas turbine provides some unique

challenges. Salty air for combustion has never really been a big problem for

diesel engine or steam plants. But the large amounts of air of required by

the gas turbine allows a considerable amount of moisture to enter the

engine, therefore the engine needs to be adapted to prevent corrosion and

the blocking, by salt deposits, of

passages. Another challenge that has to

be considered with the gas turbine is the shock that a turbine is exposed to;

pitching rolling, propeller vibrations and such. Proper care must be

exercised to the design and maintenance of support and dampening structures.

Click on the picture to the right to view a controls diagram of the marine

gas turbine.

Power to the shaft...

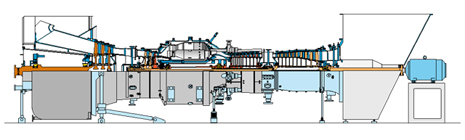

One of the gas turbine�s advantage is that power developed is usually what is wanted; a rotation force to turn a propeller or generator. It�s competitor, the internal combustion engine, operating on the batch process (intake, compression, etc) and it�s inherent mechanical losses from the acceleration and decelerations of the pistons cannot compete with the fluid process of the gas turbine. Unfortunately, the high rotational speed of the turbine is not the best speed for a propeller; which is most efficient at around 100 rpm. The remedy for this, is the coupling of a gear box to the gas turbine�s output. This allows the gas turbine to operate at it�s most comfortable torque characteristic - high speed. The reduction gear box adds to the complexity of the set up, but allows the turbine, especially the single shaft gas turbine, which have poor torque characteristic at lower rpm, to operate at their ideal speed. The speed of the turbine is less critical in a series turbine which has excellent torque characteristic at most speeds.

Get moving...

The ship needs to go forward and reverse, how is that done? One way is

the controllable pitch propeller (CPP). It allows the engine to rotate at it�s

ideal rpm independently of the loading on the propeller. Another words, the

shaft and propeller can turn at full rpm yet the propeller is not moving any

water - in neutral. Until such time the controls tell the propeller to change the pitch

of the propeller blades - allowing it to move water. In contrast, diesel

engines have the ability to run in the opposite direction, which means the

propeller shaft could be connected directly to the engine without needing a

reversing gear box or CPP system.

One common setup of gas turbine powered boats is the use of water jets. This type of propulsion is effectively a big water pump driven by the gas turbine, with the water output directed where desired. This type of setup is common on the fast ferries and private yachts. Water jets are not exclusively driven by gas turbines, it is quite common to see a diesel engine driving the water jet unit.

Classifications of Gas Turbines...

Gas turbine prime movers are classified in one of two categories: the aero derivative and industrial engine. The aero derivative engine is an aircraft engine adapted to marine service. This is done by changing some components, or even coating them to properly function in the salty air of the marine environment. One example is the General Electric LM2500, weighing in at a thrifty 34,000 lbs (with mounts, enclosures and such) provides one horse power for every 1.5 pounds. In comparison, an industrial gas turbine like the GE MS5000, used in natural gas compression, provides 20,000 hp but weighs in at 200,000 lbs - 10 pounds for every hp. This is due to it�s heavier construction. For further comparison; weight and volume of the machinery required by a 20,000 shp ship is about 100 tons for aero derive gas turbine, 400 tons for industrial gas turbine, 700 tons for diesel, and 800 tons for a comparable steam plant.

One benefit of the aero derived engines is the short amount of time for the engine to reach full operating temperature, this is due to the relative small amount of material used in it�s construction. As oppose to an industrial turbine, and the more common, diesel engine or steam plant. These must reach proper temperature before being fully loaded, this can take, in some cases, many hours.

The gas turbine gains popularity...

The application of the gas turbine, as previously mentioned, has seen a bit of reversal of fortune. The traditional customers of gas turbines had been primarily the military. With the experience gained since the first gas turbines in the 1940, and recent developments of fast ferries has made ship owners realize that a fast vessel can be profitable, and that consumers want it. This has given way to explosive growth in this field.

In the case of fast ferries, the emphasis is on "fast". Which means you need to be light, a challenge which has been met with various degrees of success by the diesel engine. Naturally, the gas turbine has been nipping at the heels of diesels for a long time. The light, powerful gas turbine is an attractive alternative to diesels, and with the weigh/space saving, the expense is somewhat comparable. The initial cost and the daily fuel cost seems to scare some of the would be owners. But I think it�s important to mention that the overall cost, where many factors must be considered will provide a clearer picture.

With all this attention in the fast ferry world, the gas turbine has been

garnishing allot of other enthusiast. High end private yachts have been

installing more and more of them, they are affectionately know as "hair

dryers". The major stumbling block in it�s acceptance in the

commercial shipping circle is it�s inability to burn the cheaper, dirtier

heavy fuel oils. But this is only a matter of time. ABB

has been testing it's

heavy fuel burning gas turbine for some time now; and with the installation

of a gas turbine generator aboard Celebrity's

cruise ship MV

Millennium, the owner

and operators can get "warmed up" to the idea of a large commercial set up.

of other enthusiast. High end private yachts have been

installing more and more of them, they are affectionately know as "hair

dryers". The major stumbling block in it�s acceptance in the

commercial shipping circle is it�s inability to burn the cheaper, dirtier

heavy fuel oils. But this is only a matter of time. ABB

has been testing it's

heavy fuel burning gas turbine for some time now; and with the installation

of a gas turbine generator aboard Celebrity's

cruise ship MV

Millennium, the owner

and operators can get "warmed up" to the idea of a large commercial set up.